Particle Segregation

This is part of my research in collaboration with Dow and P&G, funded by the National Science Foundation.

When it comes to challenges in bulk material handling, no discussion would be complete without touching on segregation.

After water, granular media are the most ubiquitous precursor material used in industry with an estimated annual consumption exceeding 1 trillion kg.

Segregation, or “demixing,” of granular materials differing in size, density, or other particle properties is problematic in many circumstances with broad implications in situations ranging from material handling in the pharmaceutical, chemical, and processes industries to natural phenomena such as debris flow and sediment transport.

We want to engineer approaches to suppress segregation so that granular materials remain mixed.

Left: Large blue and small red particles of the same density.

Right: Heavy blue and light red particles of the same size.

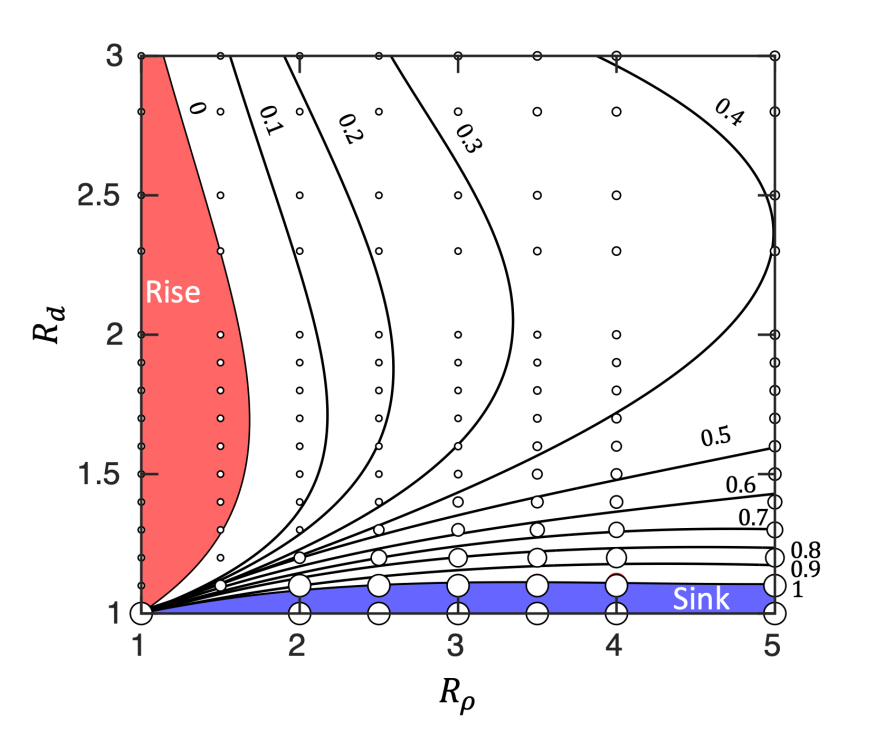

Prevent segregation by choosing the right combination of size and density

420 numerical simulations were conducted using code running on CUDA-enabled GPUs (RTX3090) for different combinations of size and density ratios to find the optimal combination of particle size ratio \(R_d\), density ratio \(R_\rho\), and mixture concentration \(c\).